Richard Schofield's Build Page

Let's Talk Engines

Right, I know the Series 1 never had a V12, nor did the series 2 for that matter,

but there have always been two things I've wanted

1) A V12

2) A Series 1 E-Type Roadster

Slightly non-compatible issues here.

V12 Power!!!!

So, I got as far as buying a V12 donor car.

This is the 6.0L Jag V12 from a 1993 XJ40.

The engine runs perfectly. I decided to run the car for a while to see how I got on with it. The car needed a bit of work to get it through an MOT, but once on the road, I had finally owned and run a V12.

.

Work at this point had stopped on the car. I had to decided if the V12 was a great idea.

I knew it meant the car would be very front heavy. I was willing to sacrifice handling just for the V12, the issue came with the amount of chassis modifications needed to make it fit.

It was almost to the point where I would either need to re-engineer the front end.

Or sit the engine so far back that legs would have to be sacrificed.

This fear of cannibalising two great cars and being left with a mess that isn't going fit forced me to consider other options.

Bye Bye V12....

V12 Sound

It's all very tempting, but....

Straight Six Power

Ok, so the V12 was out. If I couldn't have a ludicrous V12 then it needed to be something light and quick with the right sound.

This rules out a Jag six. They are so heavy. 250kg+. That's just 50kg shy of the V12.

To achieve lightness and power I had to think more modern.

The solution was a BMW 2.8 M52B28 TU. An easy 220 hp, great straight six sound, super light weight manual gearbox, modern reliability and lots of complicated wiring

(wait, that last bit's a bid thing!)

It still doesn't fit

On my first attempt of getting the engine in there were lots of clashes. The main culprits are the power steering pump (I don't need that) and the alternator (I do need that, but I'm sure I can relocate it at a later stage).

The inlet manifold on these engines is also huge and really gets in the way. The BMW normally sits rotated 30 degrees (leaning to the passenger side) form the vertical. I'm planning on mounting this engine vertically as it will be a better fit.

This does mean that the inlet manifold has to go as I'd have to re-engineer quite a bot of the chassis to make it work. It also means I have the perfect excuse to build individual throttle bodies.

Get in!!!!

It will fit if you believe it to be so!

Stripping the fat off the engine!

Here is how much slimmer it all looks now the alternator and power steering pump have been removed.

The big ugly plastic inlet manifold is still in place, but it wont be for long.

Like a glove!

Finally, engine (at least what's left of it) is in the right place. This is a nice milestone to reach.

Sump Modifications

Now that the engine will sit vertically, the sump and oil inlet pipe needs re-desining.

It may look a little Heath Robinson, but the sump has been Tig welded (I outsourced this) using thick 5mm ally.

I've designed it so it holds a comparable volume of oil to the old sump (well almost). I was really worried about ground clearance so couldn't be overly generous. I plan on building a skid plate for it later on for added protection.

Engine mounts welded on

Engine mounts made out of 5mm thick steel plate. All tigged together and tigged onto the frame.

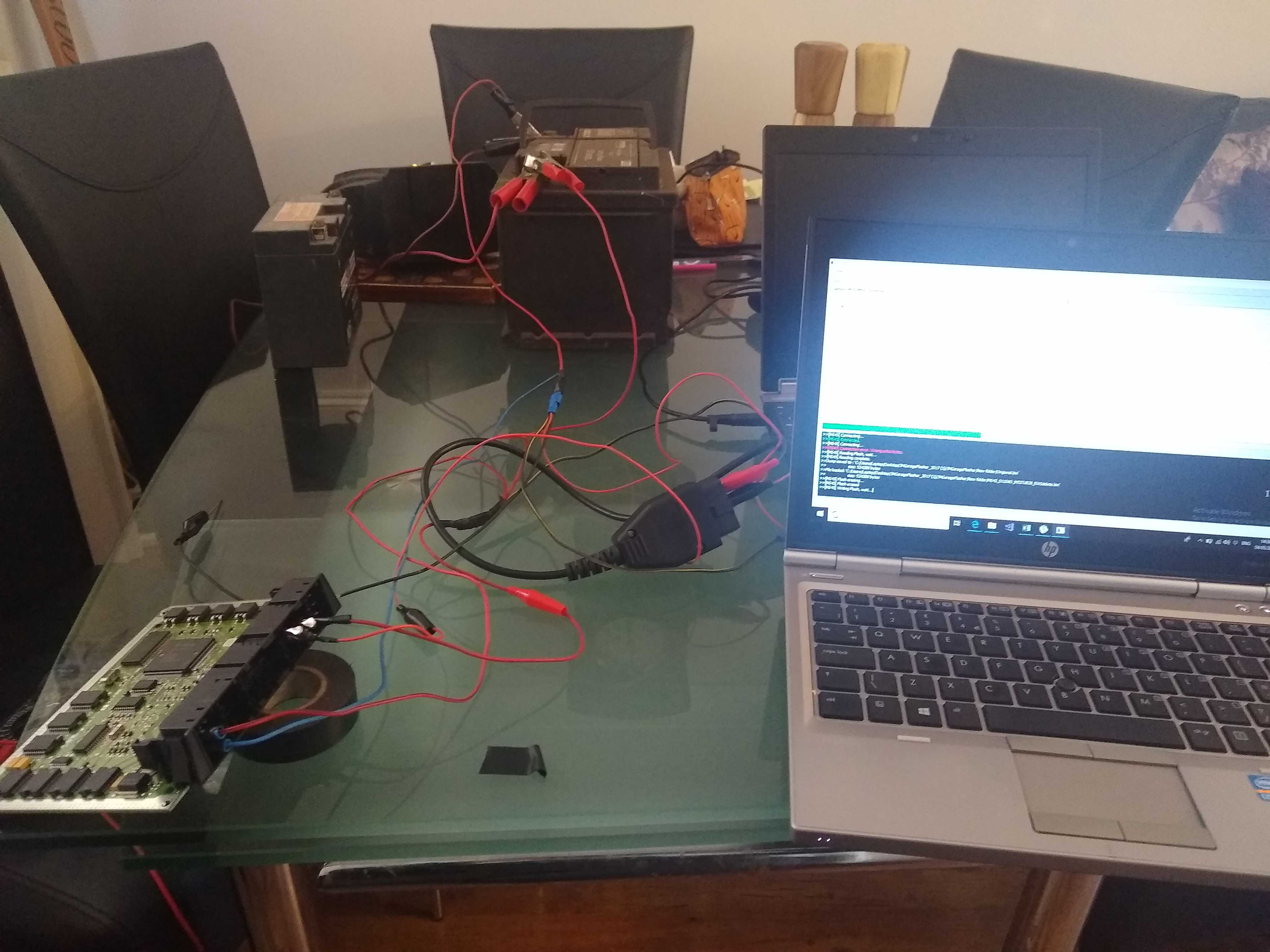

Re-programming the ECU

One thing I was a little worried about was all the electrickery on this 1999 BMW engine.

To save a bit of money I aim to use the stock ECU. This means modifying the ECU so it doesn't have an immobiliser on it.

Special cable bought, some open source software on my laptop, new map downloaded from the internet and the ECU was flashed with the new code.

Zero feedback. Might have worked???

This bit took me an entire day!!!!

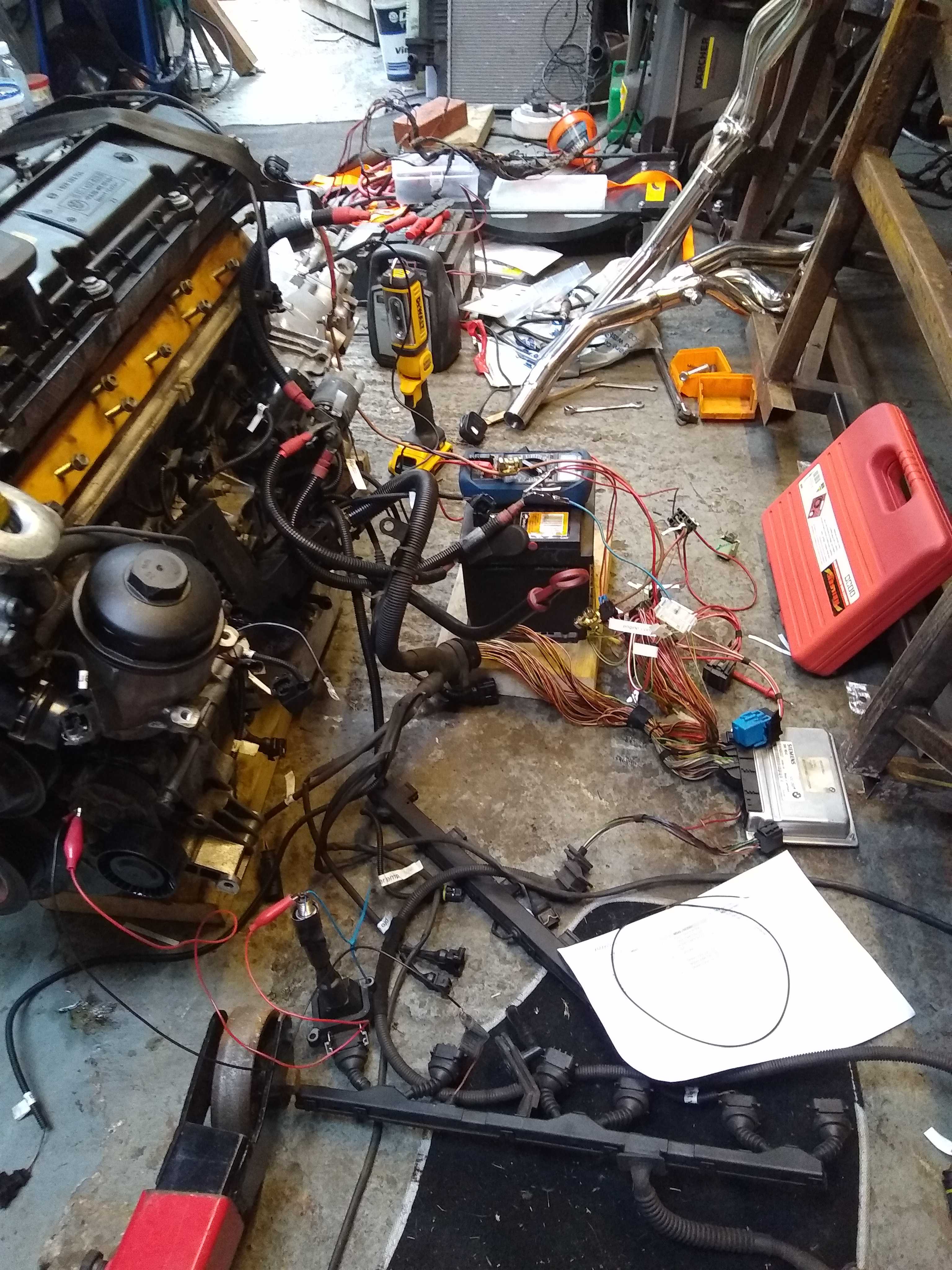

This wiring loom drove me insane.

All I wanted to do was connect up the re-programmed ECU to see if I'd tricked it into thinking it wasn't stolen, and allow the plugs to spark

Long story short, getting the right wires connected up took a lot of guessing and trial and error.

Eventually, I got my spark!

Chassis cleaned up a bit

Welding almost done, just needs a little bit more cleaning, more minor welding, before I can blast it down and get it painted.